Complete Blade Retention Schema

"bladeRetention": {

// ═══════════════════════════════════════════════════════

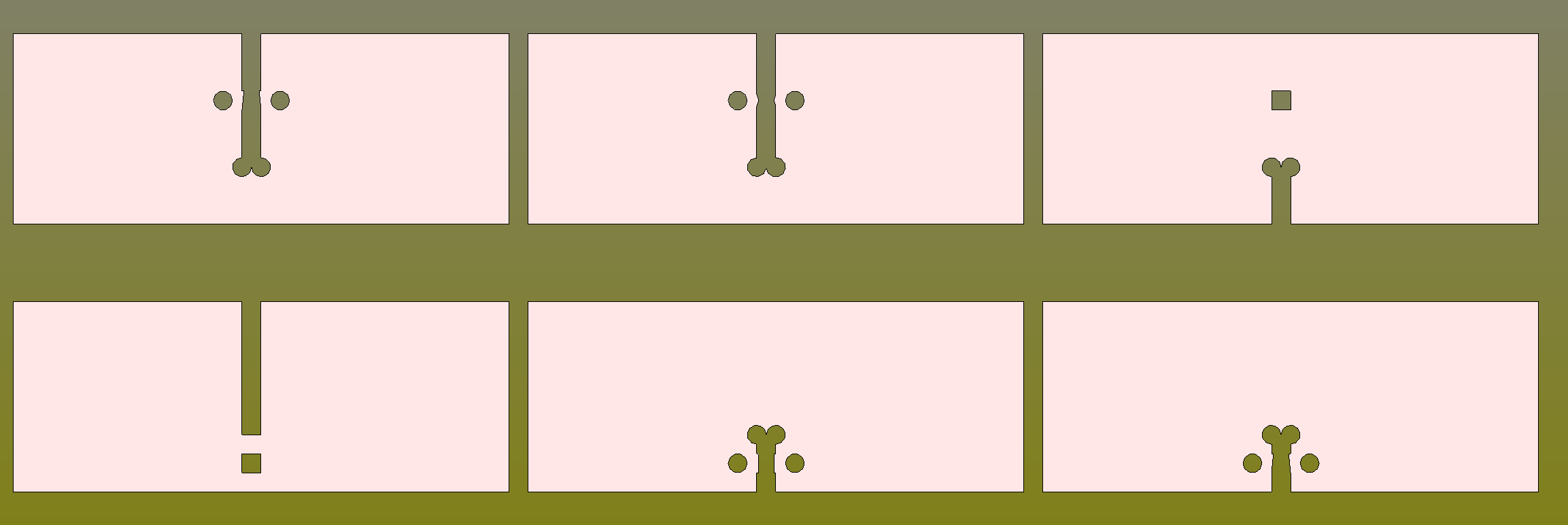

// BLADE-TO-BLADE INTERLOCKING

// ═══════════════════════════════════════════════════════

"bladeToBlade": {

"type": "keyhole", // "keyhole" | "friction-slot" | "cross-pin" | "weld-only" | "none"

// --- Slot Clearances ---

"clearanceLeft": 0.1, // mm - gap on left side of N-tab

"clearanceRight": 0.1, // mm - gap on right side of N-tab

"additionalClearance": 0, // mm - extra on BOTH sides

// --- Crossover Configuration ---

"crossover": {

"mode": "ratio", // "ratio" | "fixed"

"ratio": 0.5, // 0.0-1.0 (if mode=ratio)

"fixedHeight": 25, // mm (if mode=fixed)

"gapOrRadius": "gap", // "gap" | "radius"

"gap": 2, // mm clearance between faces

"radius": 3 // mm fillet radius (if gapOrRadius=radius)

},

// --- Keyhole Options ---

"keyhole": {

"enabled": true,

"entryDiameter": "auto", // "auto" = slot width × 2

"position": "bottom" // "top" | "bottom"

},

// --- Relief Holes ---

"reliefHoles": {

"enabled": true,

"count": 2,

"diameter": 4, // mm

"offsetFromSlot": 8 // mm from slot centerline

},

// --- Alignment Hole ---

"alignmentHole": {

"enabled": false,

"type": "square", // "square" | "round"

"size": 5 // mm

}

},

// ═══════════════════════════════════════════════════════

// BLADE-TO-BASEPLATE MOUNTING

// ═══════════════════════════════════════════════════════

"bladeToBaseplate": {

"type": "tabSlot", // "tabSlot" | "shiftLock" | "capturedNut" | "weld"

// --- Tab Configuration ---

"tab": {

"count": "auto", // "auto" | number

"spacing": 100, // mm between tabs

"width": 20, // mm

"depth": "through" // "through" | "partial" | number (mm)

},

// --- Slot Configuration ---

"slot": {

"widthClearance": 0.2, // mm added to blade thickness

"cornerRadius": 1 // mm (for CNC milling)

},

// --- Shift-Lock Options (if type=shiftLock) ---

"shiftLock": {

"shiftDistance": 5, // mm blade shifts to lock

"lockLip": 3, // mm undercut depth

"clipType": "nucleo", // "nucleo" | "spring" | "custom"

"generateClipDXF": true

},

// --- Captured Nut Options (if type=capturedNut) ---

"capturedNut": {

"threadSize": "M6", // M5, M6, M8

"nutType": "hex", // "hex" | "square"

"screwHead": "socket", // "socket" | "countersunk" | "button"

"countersinkBaseplate": true,

"nutSpacing": 150 // mm between nut locations

}

}

}

Quick Examples

| Use Case | Configuration |

|---|

| Serviceable prototype |

"bladeToBlade": {"type": "keyhole"}, "bladeToBaseplate": {"type": "tabSlot"} |

| Production fixture |

"bladeToBlade": {"type": "friction-slot"}, "bladeToBaseplate": {"type": "shiftLock"} |

| Heavy duty serviceable |

"bladeToBlade": {"type": "cross-pin"}, "bladeToBaseplate": {"type": "capturedNut"} |

| Permanent maximum strength |

"bladeToBlade": {"type": "weld-only"}, "bladeToBaseplate": {"type": "weld"} |