🆕 Locator Plate System

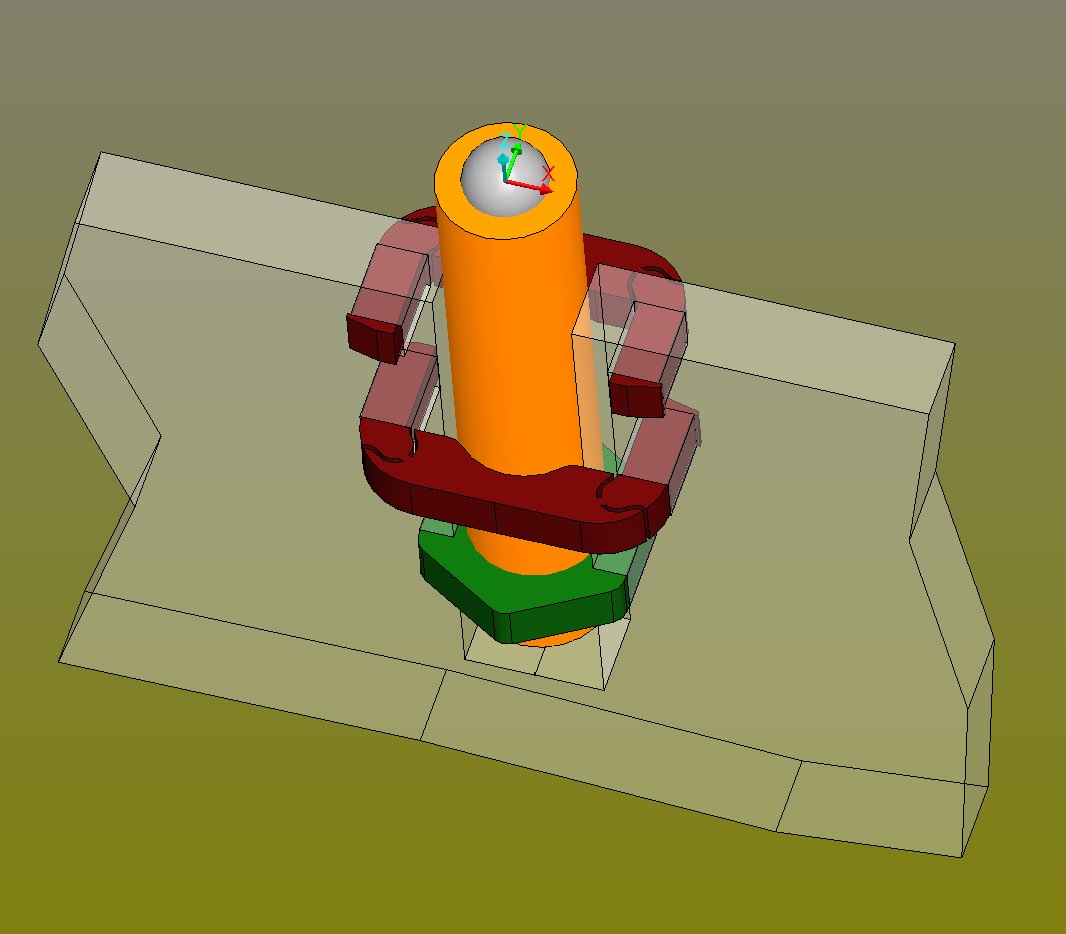

A robust plunger mounting system using top and bottom locator plates instead of threading directly into the blade. This provides better strength, serviceability, and alignment.

Assembly Overview

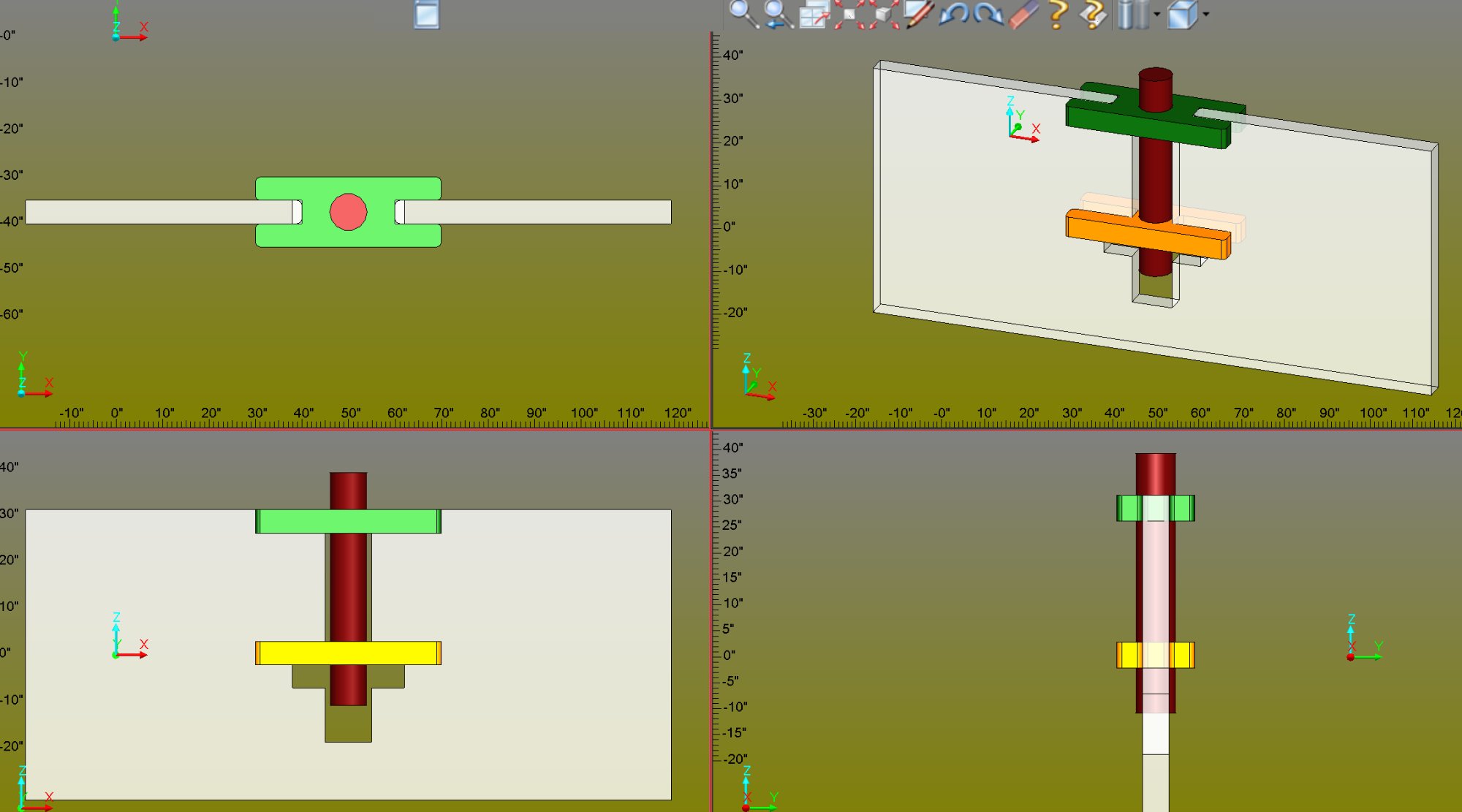

Four-view assembly showing the plunger mounting system:

Top-Left: Front view | Top-Right: Isometric view

Bottom-Left: Side view | Bottom-Right: End view

Component Stack (Top to Bottom)

| Component | Color | Function |

|---|

| Plunger Ball |

Red (top) |

Spring-loaded ball contacts the workpiece |

| Top Locator Plate |

Green |

Sits in machined recess; prevents vertical movement |

| Blade |

Gray |

Has pocket machined through for assembly |

| Bottom Locator Plate |

Orange |

Stabilizes nut; slightly different shape than top |

| Nut |

(captured) |

Threads onto plunger body; held by bottom plate |

| Plunger Body |

Dark Red |

Threaded cylinder with internal spring |

Cross-Section Diagram

PLUNGER MOUNTING ASSEMBLY - CROSS SECTION

═══════════════════════════════════════════

┌───┐

│ ● │ ◀── Plunger ball (contacts part)

└─┬─┘

│

┌─────────────┼─────────────┐

│ ░░░░░░░░░░░│░░░░░░░░░░░ │ ◀── GREEN: Top Locator Plate

│ ░░░░░░░░░░░│░░░░░░░░░░░ │ (sits in blade recess)

└─────────────┼─────────────┘

══════════════════╪══════════════════ ◀── BLADE (gray)

║ ║ ║ with pocket cut through

║ ┌───────────┼───────────┐ ║

║ │ ▓▓▓▓▓▓▓▓▓│▓▓▓▓▓▓▓▓▓ │ ║ ◀── ORANGE: Bottom Locator

║ │ ▓▓▓▓▓▓▓▓▓│▓▓▓▓▓▓▓▓▓ │ ║ (stabilizes nut)

║ └───────────┼───────────┘ ║

║ │ ║

╚═════════════════╪═════════════════╝

│

┌───┴───┐

│ NUT │ ◀── Captured nut

└───┬───┘

│

│ ◀── Plunger threaded body

│

▼

(extends below blade)

Key Design Features

| Feature | Benefit |

|---|

| Recessed Top Plate |

Green plate sits in a shallow step machined into blade top surface - prevents upward movement under load |

| Captured Nut |

Nut is held in pocket by orange plate - cannot spin or fall out during adjustment |

| No Threading into Blade |

Plunger held mechanically by plates, not by threads in potentially thin blade material |

| Fully Serviceable |

Remove top plate → unthread plunger → replace → reassemble |

| Perpendicular Alignment |

Locator plates ensure plunger is exactly perpendicular to blade surface |

Assembly Sequence

- Machine blade pocket - Cut rectangular pocket through blade with top recess

- Insert bottom plate - Orange locator plate goes in from bottom

- Insert nut - Drop nut into pocket, resting on bottom plate

- Thread plunger - Insert plunger from top, thread into nut

- Install top plate - Green plate drops into recess, capturing assembly

- Secure - Optional: spot weld or adhesive on top plate edges

Dimensional Parameters

| Parameter | M5 | M6 | M8 | Description |

|---|

pocketWidth | 14mm | 16mm | 20mm | Pocket width in blade |

pocketLength | 14mm | 16mm | 20mm | Pocket length in blade |

recessDepth | 2mm | 2mm | 3mm | Top plate recess depth |

topPlateThickness | 2mm | 2mm | 3mm | Green plate thickness |

bottomPlateThickness | 2mm | 2mm | 3mm | Orange plate thickness |

nutHeight | 4mm | 5mm | 6.5mm | Standard nut height |

plungerDiameter | 5mm | 6mm | 8mm | Plunger body OD |

⚠️ Blade Thickness Requirement

Minimum blade thickness = recessDepth + topPlateThickness + bottomPlateThickness + nutHeight + clearance

For M6: 2 + 2 + 2 + 5 + 1 = 12mm minimum blade thickness

For thinner blades, use the T-slot mounting system instead (see below).

- ✓ Design concept finalized

- ○ Pocket profile generation macro

- ○ Top/bottom plate DXF generation

- ○ JSON schema integration

- ○ Automatic placement algorithm

📦 Deliverables

fxPlungerPocket.ovm - Pocket and recess generation

fxLocatorPlates.ovm - Plate profile generation

plunger_top_plate_M6.dxf - Laser cut files

plunger_bottom_plate_M6.dxf - Laser cut files